Nowadays, it is very easy to get your favorite product, especially garments customized as per your preferences. And the increasing demand for apparel digital printing has dramatically fueled the market of direct-to-garment-printing in the past few years. And eccentric, bright, and stylish print garments are in the rage these days. People find such apparel trendy and comfy.

According to the future market insights report, the market value of the direct-to-garment-printing industry in 2022 was US$ 822 million. In another report, it was projected that the Direct to Garment printing market will reach US$ 1820 million by 2032, and the growth rate is expected to increase by 8% comparatively.

Now when talking about the key players in DTG, there are many options. Whether you are thinking of buying a new customized t-shirt for yourself or are willing to revamp your old tee with a refreshing custom-made design, visit this site to find the most comprehensive range of direct garment printing services.

What Is Direct-To-Garment Printing?

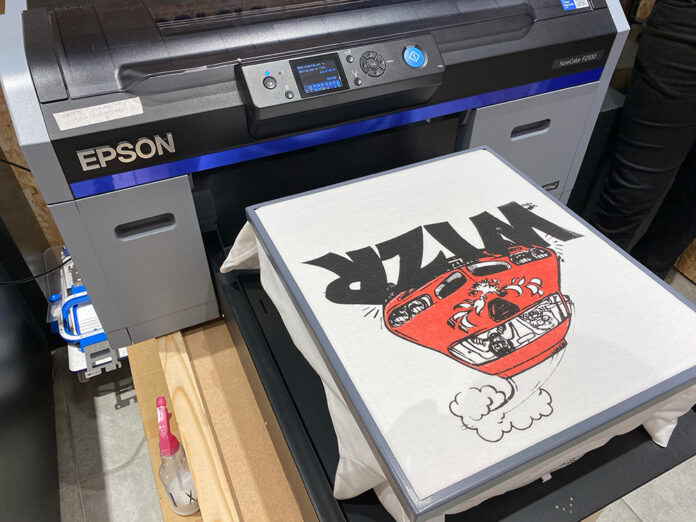

Often referred to as DTG, Direct-to-garment printing is the latest technique to print classy designs on apparel. It is spraying water-based colors or inks on garments using inkjet printing technology.

Unlike other modes, especially screen printing, the direct-to-garment print method does not require much time to set up and is less labor-intensive. It is perfect for small as well as bulk order printing. Furthermore, being the most cost-effective mode, the techniques have become a go-to business opportunity for fashion or apparel businesses and brands worldwide.

Advantages Of Direct-To-Garment Printing

With utmost cost-effectiveness and ease-to-setup, DTG methods also hold several other advantages, such as unlimited color utilization, HD image quality, detail, environment friendly, etc. Let’s discuss each benefit one by one –

Environment Friendly

The print industry, these days, is ensuring to be as environmentally friendly as possible when using inks. And the inks usually used in DTG printing are environmentally friendly. Furthermore, the process is energy-efficient.

HD Image Quality

When talking about the quality of images printed via DTG mode is exceptional. The equipment used in this offers an outstanding quality of images on the garments. Displays each detail.

Unlimited Color Palette

With DTG, brands or businesses have no limit to color usage. It means it can create classy and trendy colorful designs using the full spectrum of colors, which results in a design with the finest detailing and quality prints.

No Order Limitation

When talking about how much load or quantity DTG printers can take up, it is said that there is no order limitation. Brands can create as few as a single print garment to as many as possible in one go. Brands can print any quantity of DTG-printed garments.

How does DTG Printing work?

Many variants of DTG printers are available in the market, but a few steps must be followed. The entire process for the same is segmented into three basic steps – the pre-treatment process, the printing process, and the curing process. Let’s understand each step one by one.

Pre-treatment Step

The pre-treatment or preparation step of DTG printing involves adhering DTG inks to the fabric. This step is vital. It will prevent ink from washing off. And will enhance the vibrance of the used colors.

Now there are two ways to apply ink in the process. You can either hand-spray the colors or use a pre-treatment machine. Many manual hand color sprayers are available in the market that can be used for printing designs on garments. You must apply the proper techniques of moving your hand back and forth for perfect results.

Next, pre-treatment DTG machines are also available in the market, which let you place the fabric in the machine, select the design, and press the button; the pre-treatment will be done automatically.

Printing Process

Once the pre-treatment is complete and the garment is dry, you must place the fabric in the DTG printers for final printing. The printer first prints the under base on the material and adds the required colors to the design. Once the colors are injected into the fabric, it further enhances the vibrance of the colors on the final print.

Like inkjet printers, DTG printers also use a color palette of cyan, magenta, black and yellow.

Curing Step

Under this step, the printed garment or fabric is then put for final drying. This is done to cure the injected ink on the material. Now there are two ways to fix DTG printed garments – one is conveyor dryer drying, and the other one is heat pressing.

Conveyor dryers are widely used machines by most fashion or apparel manufacturing industries. They are used for curing fabric ink faster. At the same time, a heat press is an excellent option for businesses running on a small scale. Heat pressing is a little time taking and labor-intensive process.

Most Suitable Fabrics For DTG Printing

Since DTG techniques involve water-based ink, it is essential to use a suitable fabric to get the best result. Not all fabrics or garments are ideal for direct-to-garment prints. It is because some materials will tend to absorb the ink, creating a vivid design impression on them. Cotton, ring-spun cotton, linen, organic cotton, and other natural textiles are the most suitable fabrics for DTG.

Conclusion

In this world full of on-demand production or manufacturing, custom-made garment printing is one of the best examples. And among many customized print techniques, Direct to garment prints are gaining immense popularity. Since it is a hassle-free method of getting your favorite garment printed in the desired designs, today’s shoppers love to customize their outfits according to their preferences.

The Direct to garment print technique is a significant growth opportunity for entrepreneurs involved in print-on-demand business. It is cost-effective, easy-to-setup and there are order limitations to it. So, whether you want to establish a business or scale an existing venture, DTG has a lot of scope to offer.

![How to Design a Tiny Home [Step-by-Step Guide]](https://pmcaonline.org/wp-content/uploads/2024/01/Tiny-Home-Living-Area-218x150.webp)