Labor is one of the most expensive aspects of running a business. When your company is expanding, justifying labor spending to meet demand can be simple.

However, as your firm grows, sales level off, and it’s not long until labor expenditures spiral out of control, putting pressure on your bottom line.

You may quickly reduce worker headcount to save money at this point. Before you trim your employment, there are a variety of better strategies to reduce labor expenses and enhance efficiency.

1. Consolidate Products

Consolidating products is the practice of integrating products with the same name that exist in numerous locations as separate products into a single product at multiple locations.

Employee training can be simplified, overall productivity can be improved, and your labor costs can be reduced by consolidating items used in the manufacturing process. Purchasing higher volumes from a single vendor might also result in price breaks.

2. Reduce Perks

It’s sometimes vital to reduce your company’s operating costs – cutting employee perks and benefits is an easy strategy to reduce your staffing costs while keeping the size of your team.

The extent to which you can implement these modifications is primarily determined by the terms of your employees’ contracts. If the advantages you want to minimize aren’t specified, or if you’ve included a variation clause that allows you to adjust things, you can reduce or eliminate the perks.

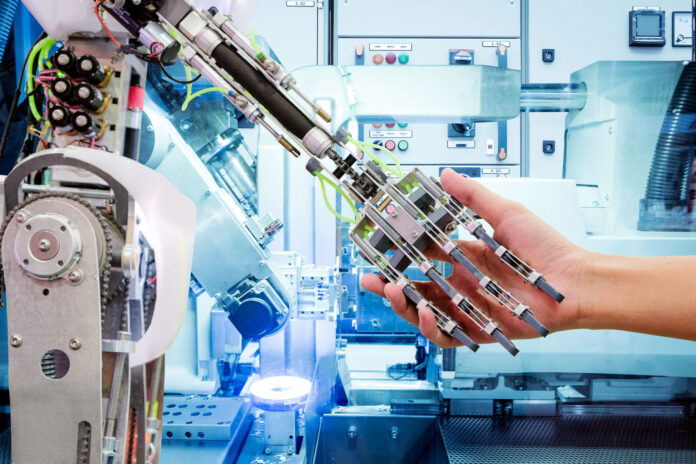

3. Automate Tasks

One of automation’s best features is that it allows you to put your ability to work and do what humans do best: come up with creative business ideas to cut expenses, make key decisions, and so on. Innovative and creative approaches that an automated system cannot replicate. So that you can concentrate your efforts on the most critical tasks.

Depending on the assignment, robots can do the work of three to five people. Help increase the productivity of your manufacturing line by getting Handling Robots. These devices can correctly and efficiently transfer objects in diverse areas thanks to their flexible and highly rigid robot arms.

4. Outsource Tasks

Outsourcing is the process of contracting with a third-party organization to execute specific tasks rather than hiring new employees or assigning those tasks to existing staff. It’s a common method for cutting costs and streamlining processes while still accomplishing vital tasks.

If you ship your goods from China to sell at Amazon, you can outsource shipping and logistics who will ensure hassle-free express transport of your products from China to Amazon warehouse. Outsourcing logistics management improves operational efficiency and lowers costs while also providing technology, knowledge, and skills to assist your company’s growth and evolution.

5. Invest in Innovative and Efficient Technology

We live in a constantly changing world. Invest in modern equipment to improve your staff’ productivity. New technology and equipment can help to simplify and streamline manufacturing processes while also delivering a quick return on investment.

If you are in the market for valve solutions that will enhance durability and constant functionality of your manufacturing plant even in harsh operating environments, purchase DomBor industrial Valves from Dombor.com. DomBor valves are of top quality and are trusted by global brands.

6. Provide Excellent Training

A well-trained workforce boosts productivity while lowering rework. Establish a training strategy for staff that includes both initial and continuous training to ensure that they are up-to-date. Training will boost labor productivity, resulting in increased production and profit for your company.

The requirement for supervision is minimized as a result of training. A well-trained person produces more; performance is increased, and well-trained people who are skilled at their jobs are in a better position to boost morale. For employee upskilling that puts them at the heart of digital transformation, partner with AllenComm.

7. Reduce Turnover

Retaining your current employees is the best way to cut costs. The cost of turnover includes the time and money spent promoting and recruiting new employees, as well as training and a three-month onboarding period during which the employee reaches expected productivity levels. Still, that doesn’t begin to account for the loss of problem-solvers and innovators who are familiar with your best practices and customer service strategy.

Getting to the heart of what your employees want is the first step in developing a retention plan. Talk to your employees and teach your supervisors how to ask about their problems.

8. Make Use Of Proper Supplies and Equipment

If your expenditures are rising, it may seem logical to buy less expensive supplies and equipment to counter rising employee compensation. While this may work in the short term, it will increase your costs in the long run by making your employees’ duties more challenging.

It can also increase the number of customer complaints, making your employees’ duties more difficult. Talking to manufacturers about even the most basic supplies can help you uncover ways to improve customer relations and cut down on wasted time.

Conclusion

Cutting your labor costs will increase your company’s net profit and profit margin. Lowering your business costs can help you increase your profit margin. Using these cost-cutting techniques will benefit your firm in numerous ways.

If you’re looking for cost-efficient and high-performing technology, Technodigm provides such equipment including dispensing valves that enable precise and rapid delivery of materials.