From prototyping to art-making to product manufacturing, machining has generally become more precise and efficient with the advent of CNC machines. In addition to enabling faster production, these tools have automated many high-tech woodworking processes and opened the door to the production of items that cannot be done manually.

Benefits of CNC

In particular, CNC machines drastically improve efficiency because they enable faster production. Not only do they automate time-consuming processes when done manually, but they can also create accurate copies of the finished product at high speed. This, in turn, allows you to generate more at a lower cost.

Another advantage that is often overlooked is the reduced cost per product due to the increased efficiency of the material. By organizing the cuts on the board and minimizing empty space, waste can be significantly reduced.

Thanks to this modern technology, many needs are quickly and easily solved in an industrial solution. Numerous changes have taken place in the field of industrial control, so with the advancement of technology and control, it has progressed. CNC technology has improved over time and is now an indispensable solution in many complex industrial companies.

Below you can read more reasons for their wide application in mass production.

1. The development of modern technologies contribution to facilitating the production

Just imagine how it used to be. Here, for example, imagine how jewelry used to be produced. The whole process was done manually, and it took the jeweler several weeks, even months, to make a unique product.

Today, production is much easier for jewelers. Thanks to the CNC router, non-ferrous metals such as gold, silver and brass are processed quickly and easily. The material is cut, processed, matted, engraved faster, and everything that used to be done exclusively by hand is now machined. There is no more time for long-term production because if you are not the first, you will be eaten by the competition. CNC technology can also be used for processing copper and other metals, which can significantly expand the business. For more information, you can visit https://www.steelproductsdirect.com.

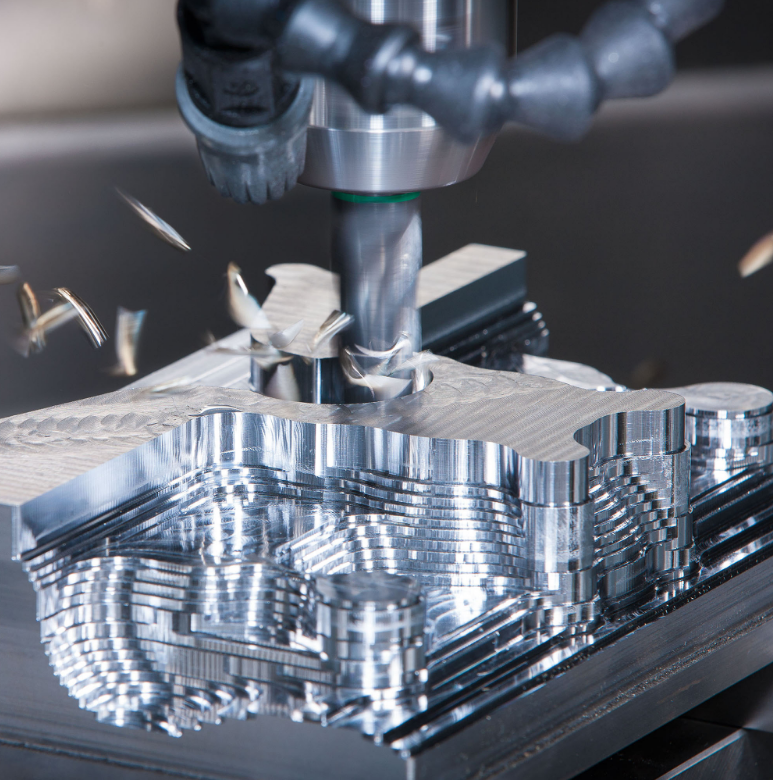

2. Advances in machining

The industrial application of digital technologies, especially clouds, but also artificial intelligence, is a revolutionary trend that is changing the sector as a whole. It marks the arrival of a new alliance between man and machine, greatly expanding the field of possibilities.

With the sophistication of IT tools and the work of Internet networks, monitoring, evaluation and automated decision making enable the optimization of production processes at all levels. CNC machining is shifting from local production to cloud platforms like 3D hubs, which is much more cost-effective.

3. Better efficiency

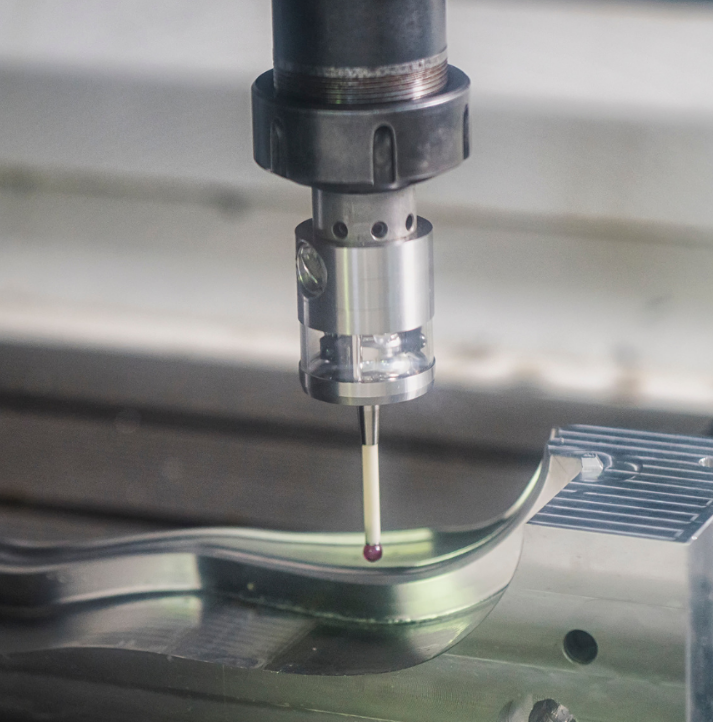

CNC machining online today has many benefits for engineers. First, it has great flexibility and endless possibilities, providing free impetus to creative innovation. Moreover, due to the possibility of choosing 3D printing, they have a wide range of materials. This technology allows for better leverage research to reduce costs. In addition, CNC machining offers significant time savings by reducing traditional waiting times.

4. Small investment and huge flexibility

With the increase in technology, design tools, simulation tools, and 3D printing, it will take relatively little skill to produce something. In the past, industrial production required large capital investments and a lot of skills. Flexibility in this field is absolute, and all it takes is a little extra workmanship. It’s all a matter of moving from one place to another… and in the opinion of many, it will have to be simplified in the future.

According to many manufacturers, training for working on CNC machines is not too complicated, so often, the manufacturers themselves or their distributors provide training to work on them in addition to the purchased machines. As in any production in the industry, there are machines that are more or less complex, and for some machines, it takes more time to operate, while for some machines, the training is much simpler.

For example, if the machine is more complex, like 5 axis CNC router, then the company hires experts who will train employees to work on new technology. Click here to see the most advanced CNC currently on the market, 5 Axis CNC Router.

5. It is profitable to invest in CNC

It should be especially emphasized that the purchase of CNC technology is more than profitable. But in order for the investment in these machines to pay off, in order for the production costs to be reduced and the investment to be returned quickly, there must be a good and realistic business plan. At the same time, it is necessary to research the market and review the offers that manufacturers of modern machines have.

And the price is affected not only by the manufacturer but also by the performance that the technology possesses as well as the complexity of the machine itself. The development of these machines is parallel to the development of new technologies, so it is not surprising that their evolution lasts from the industrial to this technological revolution, and the question is when they will be completed.

6. Possibilities of CNC technology

Apart from industrial production, CNC technology is also used in bars around the world. Yes, yes, you read that right, CNC technology has found its place there as well, and here’s what many bars have come up with. Namely, today, thanks to CNC machines, it is possible to cut the ice into unusual and interesting motifs, objects and thus create a new experience when drinking.

Although thanks to these modernism machines, it has expanded significantly, the quantity is not a loss of quality. What does it mean? Namely, although thousands of pieces of a certain product are now quickly and easily produced, it should be noted that the products will be of high quality, regardless of the fact that their number is large because the standard must not deviate from the set parameters. For more information, you can visit

7. Production of several different items at the same time

New technology has not only accelerated, but also significantly expanded production, so it is ideal for mass production. This means that only one product no longer has to be produced. Namely, while the production of a series of a certain product is in progress, it is possible to load another program that is used to make the necessary tools or to produce something else.

Everything turns in favor of the manufacturer, and if you also want to improve and quickly become competitive on the market, then browse the sites and inquire well about buying new machines. Many experts advise that it is best to buy a CNC machine that is used for wood processing, because it usually comes in a package with software that is used for machine modeling, and at the same time allows for an easy change of activity.

Using modern technologies like a solenoid valve can greatly contribute to mass production by offering automation, precise control, quick response times, and reliability, and is definitely one of the best ways to improve production efficiency and overall profitability for businesses. Their versatility makes them valuable components in a wide range of manufacturing applications, contributing to increased efficiency and consistent output in mass production settings.

Conclusion:

Idea and creativity have always been key to any business. That is why CNC technology has helped many to succeed. It is fair to say that these technologies are a sure guarantee of success.