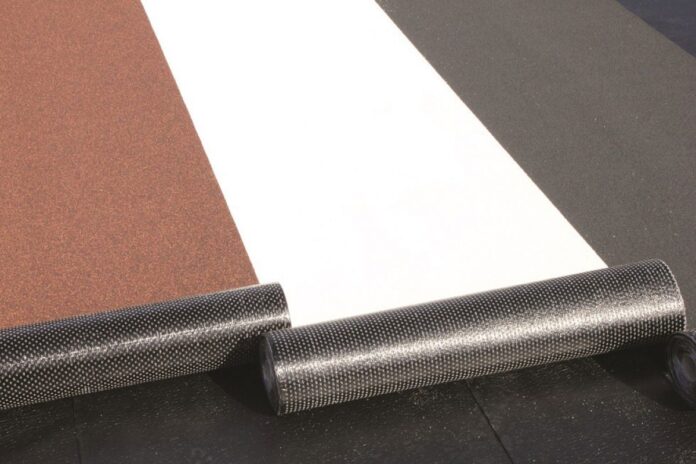

Bitumen roofing membranes are common in construction for many projects. They are a lighter, faster, and more versatile application than traditional roofing materials.

However, the two commonly used varieties of bitumen (Atactic Polypropylene and styrene-butadiene-styrene) membranes can have different applications and benefits that you may not be aware of.

This post will cover significant differences and similarities between APP and SBS bitumen membranes in construction.

Differences

APP can withstand more weight than SBS

This means that APP can be used in harsher environments; it can withstand more weight for extended periods before replacing it. That is because APP is more resistant to weathering and cracking. In comparison, SBS can only withstand a certain amount of weight before it needs replacing; once it has reached its limit, it will suffer from degradation and damage.

SBS membrane cannot survive as long in harsh weather compared to APP

Both products absorb water quickly when exposed to rain or wet conditions, but the SBS membrane will absorb the water much more quickly than the APP membrane. After being exposed to rain, the SBS membrane will become soft and have a greater chance of damage caused by heavy traffic.

In contrast, APP will stay much harder and stronger than SBS after exposure to wet conditions. That means the APP membrane will last much longer in harsh weather; it may need to be replaced more frequently than the SBS membrane, but it will last for an extended period in wet conditions.

They have different hardening capabilities in different climates

SBS membranes do not harden in cold climates, while APP polymer bitumen membranes will harden in cold conditions. That is because the APP membrane is made from materials that are more resistant to weathering than the SBS membrane.

In comparison, SBS rubber-based bitumen membranes degrade very quickly in the winter; if exposed to freezing temperatures and strong winds, they may crack and change color. By contrast, the APP membrane retains its strength during these challenging situations – its properties also help to prevent cracks from occurring as a result of heavy traffic or heavy frost. Further, APP bitumen membranes will soften in the winter and will likely crack under pressure.

Number of coats required to complete a surface treatment project

APP membranes allow for one coat, whereas with an SBS membrane, three coats are recommended by most manufacturers. This increase in coat applications is that SBS polymer bitumen membranes protect against more than just water. Like concrete, the membrane sits on top of and protects the asphalt underneath it.

If water penetrates the asphalt and cracks, water could find its way through to the underlying layer. Instead of responding by cracking and crumbling, the bitumen would continue to be recycled into a finished road surface and therefore does not affect trafficability or other features associated with asphalt roads.

Similarities

Both membranes protect against ultraviolet radiation

This means they are better at protecting steel structures, concrete, and asphalt paving from degradation caused by sunlight. Many materials will deteriorate in sunlight; this leads to a breakdown of the material’s composition and can cause it to become brittle and crack, making the surface unusable.

For instance, the Technonicol polymer-bitumen membranes prevent this because their protective coating prevents UV light from degrading the material underneath. That means that these surfaces will be more effective for longer when exposed to sunlight; in addition, exposed surfaces remain dry and safe for people to walk on.

Both membranes absorb water more quickly than traditional bitumen surfaces.

In both cases, there is less chance of water pooling on the surface, and the risk of the membrane being torn is significantly reduced. That is because it takes longer for water to soak through to the base layer in traditional bitumen surfaces compared to APP and SBS bitumen membranes.

By having a quick absorption rate, both products are also better at keeping roads and pathways dry when it rains; they do not cause puddles to form in one place, as they quickly absorb water and spread it across the surface.

Both membranes protect the base layer from physical damage caused by foot traffic

The base layer is typically made of a mixture of gravel, sand, and coarse aggregate; it is designed to support vehicles and people walking over it. However, when this base layer is exposed to heavy traffic or vibrations from heavy machinery, the surface can become damaged.

In traditional bitumen surfaces, the top layer does not protect the bottom from damage caused by wear and tear; however, the two membrane products absorb the impact of heavy objects and prevent damage to underlying layers.

Both membranes have an anti-slip surface

This means neither product can be scratched or damaged easily and are resistant to cracks; they do not soften in wet conditions, so walking over them with dry or wet shoes does not damage the surface.

This is important for construction sites because if a person slips on a surface, it may cause them to fall over and sustain injury. In addition, the anti-slip surface also prevents water from pooling on site and forming puddles; therefore, construction sites remain much safer for people to work on.

Both have soundproofing features

Both stop noise from traveling from one side of the construction site to another

This is because both products are designed to dampen vibration and absorb sound. Construction can be noisy, but bitumen membranes reduce the amount of noise that travels across the construction site, keeping people and vehicles safer. That means they are preferred by contractors and construction companies to control noise pollution around their projects, as well as safely manage water sustainability onsite.

There are many differences and similarities between APP and SBS polymer bitumen membranes. Both of these products are used within construction, particularly on roads and pavements, to protect the surface from damage. They offer protection against water, sunlight, and noise pollution and prevent different degradation factors, including temperature change and UV radiation.

The primary difference between these two waterproofing membranes is that APP can survive in harsher climates for extended periods as it is more resistant to weathering than chemicals used in SBS rubber-based bitumen membranes.